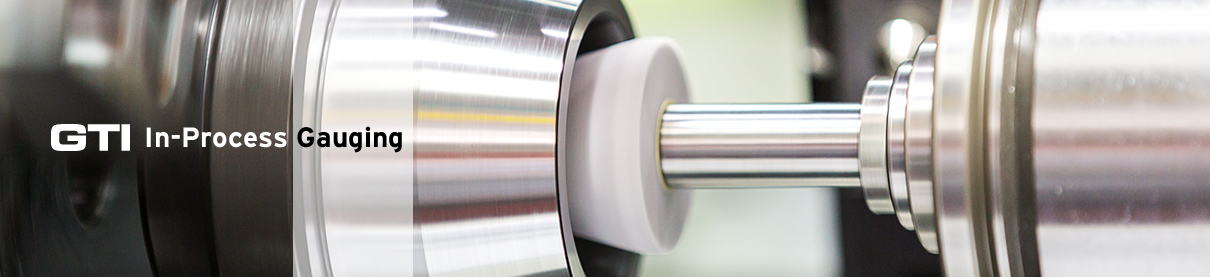

Precise, Highly Durable In-process Gauging Components

In-process gauging for high-production grinding applications involves measuring a rotating workpiece through continuous contact during machining. The result, the gauge is deep in the harsh machining environment where it is repeatedly introduced to the part between cycles. For both ID and OD grinding applications close proximity to grinding wheels and tooling are part of the process – collisions inevitably occur.

Perishable in-process and Post-Process gauge contacts and fingers are at the foundation of GTI’s

history. It is the product GTI is founded on and one we take extreme pride in providing to our loyal customers. With over 35 years’ experience we’ve perfected our manufacturing process to ensure quality at the most competitive prices in the industry. That experience has allowed us to perfect proprietary manufacturing techniques. Our diamonds are guaranteed not fall out during use and the surface finish exceptionally smooth so not to mark the part surface. We offer design modifications and repair programs to keep our customers from having to replace the entire steel body when the diamond tip is all that is needs.

We make everything in house from machining the stainless steel bodies to grinding and polishing all the super abrasives. This ensures our quick turnaround…24 hours if needed to keep our customers production lines from shutdown. GTI also offers stocking programs. Our customers frequently place blanket orders which we ship against based on release schedules ensuring “Just in time” deliveries. We continue to invest in the current CNC machining diamond grinding machine tool technologies to keep on the leading edge.

We can save you money, improve delivery with no compromise in quality.

Partial Selection of Our In-process Gauging Components

| Brands | Super Abrasive Materials |

|---|---|

| Marposs | Natural Diamond |

| Control Gaging | Synthetic Diamond |

| Movomatic | PCD |

| Etamic/Jenoptik | Carbide |

| TSK |